Heater

While the dash and hoses are out and strewn about the

garage/house/garden in various stages of cleaning and refinishing, I decided to

test the heater blower figuring that it would be a good opportunity in case it

didn't work.

I've been looking at Brosky's

heater page and am

puzzled. My heater unit has three wires entering it: Green/Brown, Green/Yellow

and White. The White is snipped - about 6" dangling. The other wires are

connected to the heater switch, as they should be. According to Dan Masters that

White wire should be Black, and that's as Brosky shows also in his photos.

In fact, white is also correct.

The heater blower motor was open circuit. I removed the fan

blade, and then the top half of the motor casing. Inside it was evident that at

some point there had been water ingress. The springs behind the brushes were

rusted up, and so the brushes were not bearing against the armature.

Also, there was a little charring on the wire coils, but amazingly both coils

were alright when tested with the ohmmeter. Now I have loosened the brushes,

with a little WD40, re-made the soldered connections, and am experimenting on

the bench: it spins if I hold the brushes in place and apply 12V!

I think that it will need a little while for the WD40 to soak in so that the

brushes can move back and forth freely, but right now I'm optimistic I can get

it running again.

I think the motor is irreparable ... Although I can get some

movement out of it, the armature shaft is scored and the brush channels seem to

have shrunk to the extent that I can't get the brushes to move freely in them.

Removing the fan involves removing the spring clip that

attaches the fan to the shaft, or rather seems to prevent it coming off the

shaft, then judiciously tapping the underside of the fan boss with a drift.

There is just enough clearance between the fan and the motor body to do this.

Undoing the two bolts that run through the body allow the two halves of the body

to be pried apart. There are two springs and two spaces on the bolts that easily

drop out.

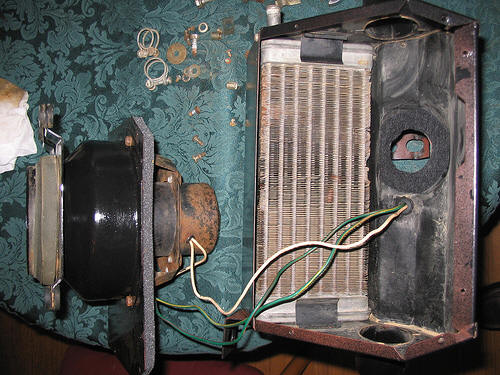

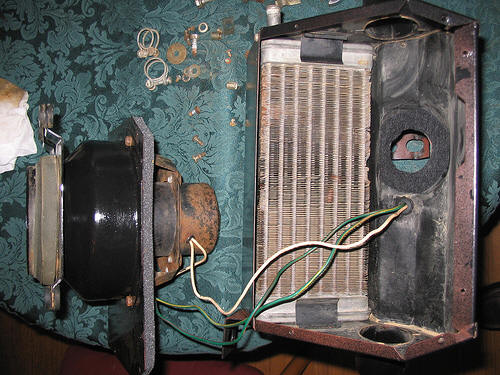

Inside you can see it's a bit of a mess, with dust, rust and blackened wires

suggesting overheating:

Showing armature and brushes:

(Large version here:

http://farm3.static.flickr.com/2329/2063866595_84b39e876d_o.jpg )

I found that the brush channels were rusted up. Today the reason for this was

discovered: the washer fluid lines were both detached from their connections to

the wiper nozzles under the dash, and so what had been happening was that every

time the washer pump was operated, water was being liberally sprayed into the

intake area of the heater fan!

The motor was clearly beyond

salvage, so I bought a used one on Ebay (which coincidentally also had a white

wire for earth). When it arrived I checked it carefully before mounting it into

the box. For reference, the series resistor that is used to provide the reduced

voltage so the fan operates at low speed is of value 2.5 Ohms.

The heater core I cleaned

thoroughly, and ran cold water through in both directions, until the water ran

clear. Here it is, placed back in the box:

I used black foam

weatherstripping at both ends of the core to minimise rattles. I cut new soft

washers from felt for the pipes. I also used weatherstripping to replace the

perished original seals at various places throughout the box. Here's the next

piece assembled on the box:

Here's the top cover, before

attaching the motor, and with fresh weatherstrip:

And then with the motor

attached:

The top cover, about to be

installed on the box: the wires are threaded through a new grommet. A new felt

pad for the base of the motor has been stuck in place, just above the grommet.

The box completely reassembled,

and with the original decals (carefully removed right at the outset) stuck back

on - but the wrong way up! When reassembling I reused all the original screws -

why buy new ones?

Back to

Overview